Grab bucket

Grab bucket

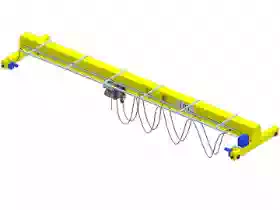

The LDZ single girder grab overhead traveling crane consists of an LDA base unit equipped with a grab spreader below. A variety of spreaders, grabs, electromagnetic lifters, and lifting beams can be fitted for different applications.

As a lightweight lifting solution, the LDZ electric overhead single girder grab crane features an integrated electric grab as its hoisting mechanism. It travels along a suitably designed runway rail system, offering overall structural rigidity. Supported by tall concrete columns or steel structures, its bridge-like configuration allows longitudinal movement on elevated tracks installed on both sides. This design enables unobstructed material handling beneath the bridge, free from ground-level obstacles. Single girder grab cranes are among the most widely used and numerous types of lifting equipment.

Control Methods

The LDZ single girder grab crane primarily offers two operation modes: ground control and cabin control. The operator cabin, available in enclosed or open designs, can be installed on either the left or right side of the crane according to site layout. Cabin access is available from the side or end to accommodate different user conditions and preferences.

Product Configuration

The LDZ single girder grab overhead crane comprises four main sections: the metal structure, the trolley and crane travel mechanisms, the electrical control system, and the hoisting unit.

1.Metal Structure: Includes the main girder, end beams, and runway rails.

The main girder is fabricated from a U-shaped steel channel welded with an I-beam to form a box-section design. End beams are similarly constructed from rolled U-channels and welded into box sections. The main and end beams are bolted together.

Runway rails and conductor bars can be supplied per customer requirements. Three installation methods are available: welded fixing, bolted fixing, or hook-bolt fixing.

2.Travel Mechanism: Consists of separate trolley and bridge travel drives.

The electric wire rope hoist and crane travel are independently controlled. Travel motors utilize soft-start squirrel cage motors with disc brakes.

Typical travel speeds are approximately 20–30 m/min.

3.Electrical System: Equipped with internationally recognized electrical components. Power is supplied via a multi-stage, seamless conductor bar system.

4.Hoisting Mechanism: Features a high-starting torque conical rotor squirrel cage motor with an integrated disc brake. The hoisting unit is designed for light-duty grab operation.

Single girder grab overhead travelling crane is mainly used to grab sand, scrap iron, rubbish, coal some bulk materials, or solid some materials.

Single girder overhead crane is a main tool and equipment for mechanization and automation of processing in the modern industrial manufacturing and lifting transportation areas. Single girder overhead grab crane is mainly equipped with light class grab for grabbing and transporting materials,so this type crane mainly used for grabbing places such as lump coal, coke, slag, cement and so on.